Frequently Asked Questions

There are many benefits to selecting European Wide Plank Flooring for your home or office. Below are some of our frequently asked questions to help you learn more about Nor-Cal Floor Design and our products:

1.) What is engineered flooring?

2.) Is all engineered wood flooring the same?

On the opposite end of the spectrum you will find our engineered wood flooring. Our planks are the ideal alternative to a solid floor. Achieving the same look without the cupping and warping. Our engineered planks are comprised of a 3-layer construction making them more stable, with less cupping and warping than a solid floor. The top, wear layer, is 4-5mm thick. The center, core layer, is vertical grain spruce laid transversely to the top and bottom layer. This reduces shrinking and swelling by 80% compared to a solid plank.

3.) What are the main benefits of engineered flooring?

4.) Can a Nor-Cal Floor Design engineered flooring product be refinished?

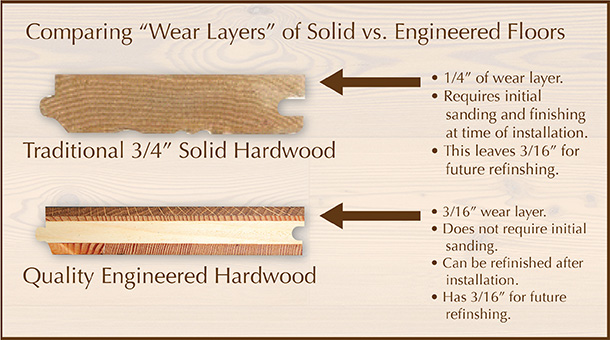

In the illustration below you see solid having 1/4” and engineered having 3/16” wear layer. This is prior to installation. A solid floor gets sanded and finished at the time of installation, leaving the wear layer with a similar 3/16” for future sanding and refinishing. A engineered floor can be finished before or after installation and does not require a sanding at the time of initial finishing leaving the 3/16” for future sanding and refinishing.

5.) Can engineered flooring be used in both residential and commercial construction?

6.) Are Nor-Cal Floor Design products environmentally sound?

Some oils do not contain wax; they are based on vegetable oils and non-aromatic solvents. The oil penetrates into the surface of the wood, and as they cure, harden to form a protective surface that becomes part of the wood floor. Small scratches and indentations caused by normal wear and tear are less noticeable and can be spot repaired.

To learn more about some of our certified green products, click here.